Optical Communication Application Materials Low Refractive Index UV-Curable Resins,Fiber Optic Communication Coatings,High-Performance Optical Adhesives for Photonics Ningbo Merak Advanced Materials Technology Co., Ltd. , https://www.merak-tech.com

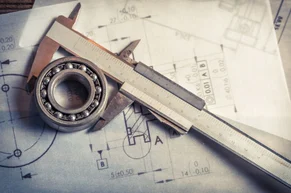

At Emerson Bearing, we know that selecting the right bearing for your specific application is essential to ensuring long-term performance and reliability. To maximize the service life of your bearings, it's important to understand the factors that can lead to wear and take proactive steps to prevent or address them.

When it comes to bearing longevity, several key factors play a role. Let’s explore some of the most common causes of premature failure and how you can mitigate their impact.

**• High Speeds** – Operating a bearing beyond its recommended speed limit can significantly reduce its lifespan. High-speed operation combined with vibration and unbalanced forces can cause excessive wear on the cage and lead to uneven running. Proper lubrication of the guiding faces is crucial in these cases. Additionally, if the bearing is lightly loaded at high speeds, it may experience slippage between the rolling elements and the raceway, which can also accelerate wear. In such situations, increasing the load slightly can help prevent this issue.

**• Rapid Changes in Speed** – Sudden accelerations and decelerations can cause slippage between the rolling elements and the raceways, leading to significant wear. To minimize this risk, consider using bearings with smaller cross-sections and rolling elements, or opt for cages made from lightweight materials like metal or plastic. Another effective approach is to apply axial preload to the bearing.

**• Lubrication and Maintenance** – Lubrication is one of the most critical aspects of bearing maintenance. However, even the best lubricants have a limited service life. Over time, factors such as temperature, contamination, and mechanical stress can degrade the lubricant, leading to increased friction and wear. Regular relubrication can extend the life of your bearings, though it may not always be cost-effective depending on your application.

**• Sealing** – Choosing the appropriate seal and compatible grease is vital for protecting your bearings from contaminants like dust and moisture. A well-sealed bearing can operate more efficiently and last much longer under harsh conditions.

**• Service Life and Operational Safety** – Bearings often fail before the rest of the machine, requiring replacement or repair. Unexpected failures can disrupt operations, but they are usually predictable if monitored regularly. By inspecting your bearings according to the load and operating conditions, you can ensure maximum operational safety and avoid costly downtime.

At Emerson Bearing, our goal is to help you achieve optimal performance and longevity from your bearings. Our Bearing Failure Analysis page offers valuable insights into the root causes of bearing failure and practical solutions to extend their life. Whether you're looking for guidance or need assistance with your next bearing purchase, we're here to support you. Explore our catalog today or reach out to us directly—we’re committed to helping you make informed decisions that benefit your business.