Thermoforming is a manufacturing process used to shape plastic sheets into various custom design products. It involves heating a plastic sheet until it becomes pliable, then using a mold or a vacuum to form it into the desired custom shape.

Thermoforming and vacuum forming are both processes used to shape plastic sheets into specific forms. However, there are some differences between the two techniques:

Thermoforming is a versatile process that is widely used in industries such as packaging, automotive, aerospace, and medical. It offers advantages such as cost-effectiveness, quick turnaround times, and the ability to produce complex shapes with high precision.

Custom Thermoforming,Thermoforming Plastic Products,Thermoforming Process,ABS Thermoforming Dongguan Yiyongli Industrial Co.,Ltd. , https://www.absthermoforming.com

1. Process: In thermoforming, a plastic sheet is heated until it becomes pliable, and then it is pressed against a mold using pressure or a vacuum. Vacuum forming, on the other hand, relies solely on the use of a vacuum to draw the heated plastic sheet onto the mold.

2. Mold complexity: Thermoforming is typically used for more complex shapes and intricate molds, as it allows for greater detail and precision. Vacuum forming, on the other hand, is better suited for simpler shapes and molds that do not require as much detail.

3. Material thickness: Thermoforming is often used for thicker plastic sheets, typically ranging from 0.030 to 0.250 inches in thickness. Vacuum forming is more commonly used for thinner plastic sheets, typically ranging from 0.005 to 0.060 inches in thickness.

4. Production volume: Thermoforming is generally more suitable for high-volume production due to its faster cycle times and ability to handle larger sheets of plastic. Vacuum forming is better suited for low to medium volume production, as it has slower cycle times and is limited by the size of the vacuum forming machine.

5. Cost: Thermoforming typically requires more expensive equipment and molds, making it a more costly process compared to vacuum forming. Vacuum forming, on the other hand, is a more cost-effective option for smaller production runs or prototypes.

Overall, thermoforming is a more advanced and versatile process that offers greater precision and complexity, while vacuum forming is a simpler and more cost-effective option for less complex shapes and smaller production volumes.

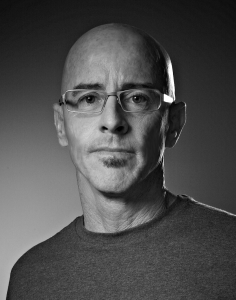

**SAN RAFAEL, Calif., March 25, 2019 /PRNewswire/ –** Autodesk, Inc. (NASDAQ: ADSK), a global leader in design and engineering software, announced today the addition of Blake Irving to its Board of Directors, effective March 22, 2019. With over two decades of executive leadership under his belt, Irving joins the board following a highly successful stint as CEO of GoDaddy. During his tenure there, he transformed the domain-name registrar into a robust global cloud platform, paving the way for a successful initial public offering.

“Blake is not just a seasoned tech executive but someone who embodies the spirit of innovation and growth,†said Andrew Anagnost, President and CEO of Autodesk. “His extensive background in cloud platforms and subscription models aligns perfectly with our vision of enhancing self-service and automation across our ecosystem.â€

Stacy Smith, Chairman of the Board at Autodesk, echoed similar sentiments. “Blake’s track record in scaling businesses is unparalleled. Whether it was Yahoo! or GoDaddy, his leadership consistently delivered impressive results, and I’m confident his expertise will drive significant value for Autodesk moving forward.â€

Before joining GoDaddy, Irving held pivotal roles at Yahoo!, including Executive Vice President and Chief Product Officer. Under his guidance, the company expanded its user base significantly, reaching almost one billion active users during his time there. Prior to Yahoo!, Irving spent 15 years at Microsoft, where he spearheaded initiatives to develop scalable cloud infrastructure solutions.

Irving currently sits on the boards of DocuSign and ZipRecruiter. He earned a Bachelor of Arts degree in Fine Arts from San Diego State University and later obtained an MBA from Pepperdine University.

**About Autodesk**

Autodesk empowers creators and innovators by providing tools that fuel imagination and productivity. From architects designing sustainable cities to engineers building cutting-edge vehicles, our software touches countless industries worldwide. At Autodesk, we believe in enabling possibilities—no matter how complex or imaginative they may be.

---

This announcement comes as part of Autodesk's ongoing commitment to fostering creativity and driving technological advancement. As Irving steps into his new role, industry watchers are eager to see how his strategic insights will shape the future of the company.

*Note: Autodesk is a registered trademark of Autodesk, Inc., and/or its subsidiaries and/or affiliates in the USA and/or other countries. All other brand names, product names, or trademarks belong to their respective holders. Autodesk reserves the right to modify product features, services, and specifications without prior notice.*

© 2019 Autodesk, Inc. All rights reserved.

---

For those interested in learning more about Blake Irving’s contributions to technology, check out the images below, which highlight some key milestones from his career.