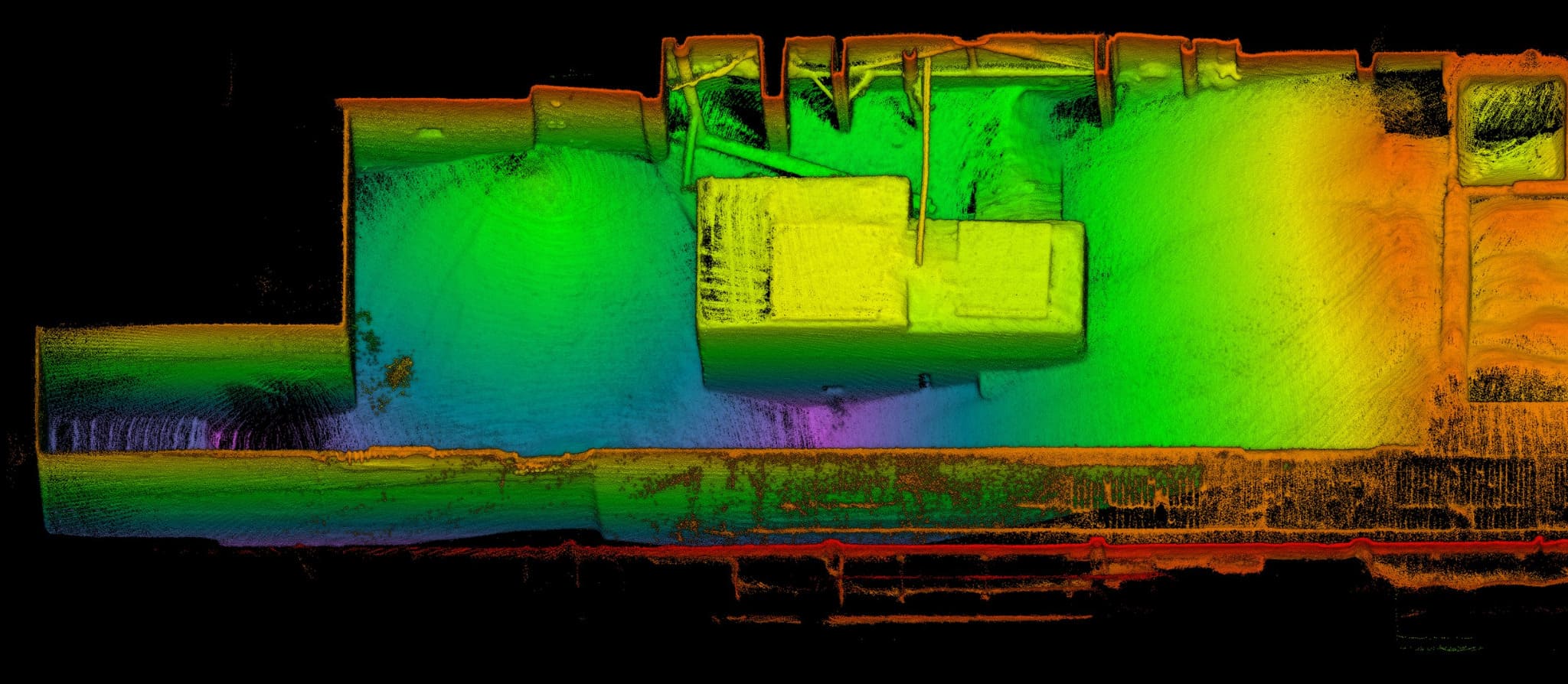

The Elios 3 drone has revolutionized stockpile monitoring at a cement plant by cutting risks and slashing inspection times, all while boosting data accuracy. Here's how it works. Safety First By using a drone, workers no longer need to climb on top of stockpiles with a GNSS rover, drastically reducing the risk of accidents or stockpile collapses. Rapid Results With the Elios 3, we can monitor 30 different stockpiles in just 7-8 flights, finishing data collection in less than two hours for a large area. Scalable Solutions We now conduct these stockpile surveys monthly, covering piles ranging from a few hundred cubic meters up to over 10,000 cubic meters.  Precision Matters The Elios 3’s LiDAR scans allow us to create detailed point clouds and perform volume calculations in CloudCompare. These measurements are accurate to within a centimeter, far surpassing "eyeball" estimates.  Managing stockpiles effectively is crucial for maintaining operational efficiency at any industrial facility. Misjudging material amounts can lead to production halts, incurring significant downtime costs and headaches for everyone involved. However, stockpile management comes with its own set of challenges: Obtaining accurate measurements is tough and risky. Traditionally, workers must climb over stockpiles with a GNSS/GPS rover, which poses a serious risk of falling or the material shifting. Every site is unique. Some require one-time measurements, while others need ongoing surveillance. Thus, a "one size fits all" approach doesn't work. Efficiency is key. Stockpile surveys should not disrupt other operations or delay essential work. InspecDrone, a specialized drone service provider based in Germany, was founded in 2018 by Simon and Susanne Kumm. They cater to diverse industries, visiting sites like cement plants, metal processing facilities, power generation stations, waste-to-energy plants, and woodworking operations. Their drone services enhance safety, minimize downtime, and deliver vital data. Drone inspections can be conducted safely from a distance One of their clients operates a cement plant with numerous stockpiles requiring regular measurement. Previously, this client relied on visual estimations and manual GNSS measurements to decide when to order new materials. However, they sought a more dependable and precise method. The goal was to assess whether the Elios 3 drone could measure stockpiles effectively, focusing on three main objectives: Track on-site materials in bunkers and piles to optimize delivery and inventory planning. Eliminate the need for workers to traverse and climb piles with a GPS rover, which is inherently hazardous. Obtain accurate measurements that can be consistently quantified. InspecDrone owns several drones and chose the Elios 3 due to its LiDAR payload, which excels in volume measurement both indoors and outdoors. Upon visiting the site, the InspecDrone team evaluated the layout. There were multiple stockpiles, some located inside a bunker and others outside. The Elios 3 is designed for confined spaces and collision-resistant flight, so the team felt confident flying indoors. Moreover, using this drone allowed them to achieve one of their primary goals right away—eliminating the need for workers to walk on top of piles. The drone could gather all necessary data. The InspecDrone team used the Elios 3 to precisely measure stockpile volumes After flying the drone around the various stockpiles, the team processed the results in CloudCompare. The storage area had an irregular shape, so Simon carefully adjusted for this during post-processing. He then began measuring the stockpile volumes using CloudCompare. Once completed, the findings were shared with the client. Following this initial survey, the cement plant requested that InspecDrone return monthly to measure their stockpiles. The Elios 3's results proved highly accurate and provided sufficient detail for plant managers to plan stockpile refills and assess current stock conditions. Now, the entire inventory of the site requires just 7 or 8 flights with the Elios 3 to cover the whole area. This includes 30 stockpiles and bunkers ranging from a few hundred cubic meters to 10,000 cubic meters. Each month, InspecDrone visits this site to survey stockpiles and prepare a report for the cement plant managers. Stockpile volumes are depicted through LiDAR point clouds with the Elios 3 In addition, thanks to creating these precise models of the bunkers, it's possible to determine dimensions and available space. Often, there are large quantities of unusable material, known as dead stock. With the Elios 3, InspecDrone can quantify these stockpiles and use them as a baseline for future measurements—whether adding to the pile or calculating remaining storage capacity. The combination of LiDAR technology from the Elios 3 and its unique design makes it the ideal alternative to conventional stockpile surveys. It's also more accurate than estimating pile levels and quantities by sight alone. With the LiDAR stabilization, InspecDrone is broadening its services at this site to include inspections of cement assets like silos. The rapid drone inspection enables safer operations while reducing downtime and costs. Through these efforts, InspecDrone achieves the goals set for stockpile surveys: accurate results that facilitate better planning and eliminate the need for workers to climb over material piles. As the Elios 3 continues to improve in accuracy and expand its capabilities, InspecDrone anticipates uncovering new and innovative workflows. The most precise surveys with the Elios 3 are performed using the surveying payload.

The finned tube is to improve the heat exchange efficiency. By adding fins on the surface of the heat exchange tube, the outer surface area (or inner surface area) of the heat exchange tube is increased, so as to achieve the purpose of improving the heat exchange efficiency. Such a heat exchange tube . Usually used for heat exchange between liquid and gas.

Finned tube is a heat exchange element. As a heat exchange element, finned tubes usually work under high-temperature flue gas conditions for a long time. For example, the finned tubes usually used in boiler or harsh environments, high temperature and high pressure, and in a corrosive atmosphere. This requires that the finned tubes should have high anti-corrosion properties, Anti-wear properties, lower contact resistance, higher Stability and anti-dusting ability.

There are many types of finned tubes, and new varieties are constantly emerging. According to the classification of processing technology, there are extruded fin tube; high frequency welded finned tubes; rolled formed finned tubes; suit formed finned tubes ; cast finned tubes; tension wound finned tubes; Inserted tubes.

According to the shape of the fins, there are square finned tubes; circular finned tubes; spiral finned tubes; longitudinal finned tubes; corrugated finned tubes; spiral serrated fins Helical Serrated Finned Tubes; pin-shaped finned tubes; integral plate-shaped finned tubes; inner finned tubes.

According to whether the fin material of the finned tube is the same as that of the base tube, it can be divided into: single metal finned tube, bimetallic composite finned tube.

Single metal finned tubes are classified by material into copper finned tubes; aluminum finned tubes; carbon steel finned tubes; stainless steel finned tubes; cast steel finned tubes.

Finned Tube,Extruded Fin,Brown Fin Tube,Longitudinal Finned Tube Guangdong Jiema Energy Saving Technology Co.,Ltd , https://www.jmheatexchanger.comMonitoring Stockpiles at a Cement Plant with the Elios 3 Drone

Key Benefits in Brief

Revolutionizing Stockpile Measurement with Drones

Monitoring Cement Stockpiles with the Elios 3

Ongoing Drone Surveys for Stockpiles

Expanding Drone Inspection Services